Let’s start with the basics

Filtration is the process of separating solids from liquids through a filter medium, a material allowing liquid to pass through it while blocking solids. When it comes to filtering liquids, there are two main types; surface and depth.

So, what’s the difference?

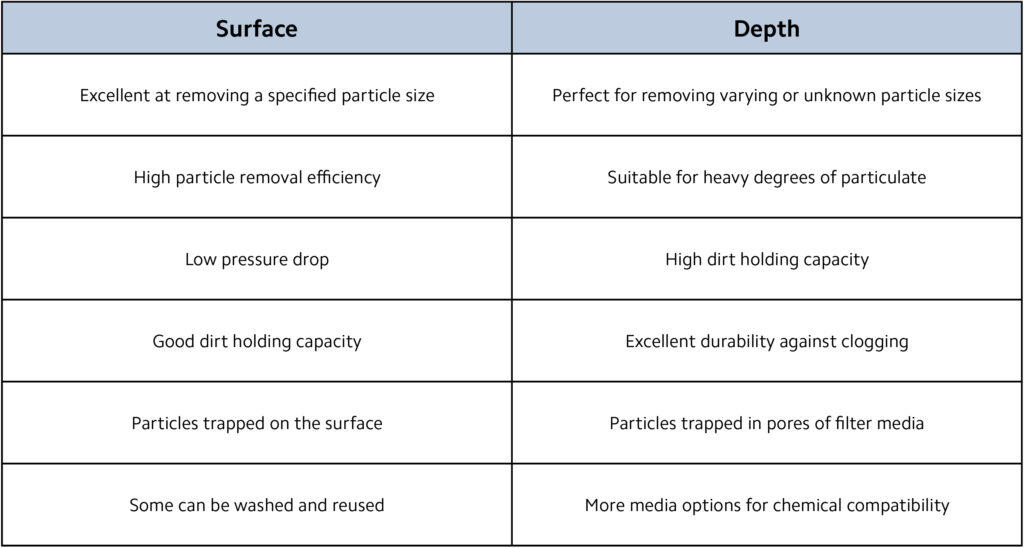

First up, we have surface filtration. As the name suggests, this technique works at the cartridge’s surface. Surface filtration is perfect when you know the size of the particles you want to bid farewell to and it’s also great for applications where you need to handle lots of dirt without compromising on pressure drop or loss.

Then we have depth filtration, providing a solution within filter medium depths. This method captures particles deep within the filter material’s pores. Depth filtration is the go-to for when you’re dealing with unpredictable particles, or even a bunch of unknown misfits.

Understanding the difference between these filtration methods is crucial for achieving optimal filtration. When designing a filtration system for your application, choosing the right technique can make all the difference to your desired end product, as well as optimising costs, pressure drop and flow rates.