Why does side stream filtration on closed loops reduce maintenance costs?

Closed loop systems harbour dirt, sludge and scale as well as swarf debris and microbiological contamination from within the system which cause issues of blocking and corroding of the pipework.

Side stream filtration helps to capture and remove suspended solids as it is usually installed at the lowest water velocity, allowing for the greater accumulation of suspended solids. This is the method recommended by BSRIA (Building Services Research and Information Association) a professional body providing specialist expertise in construction and building services.

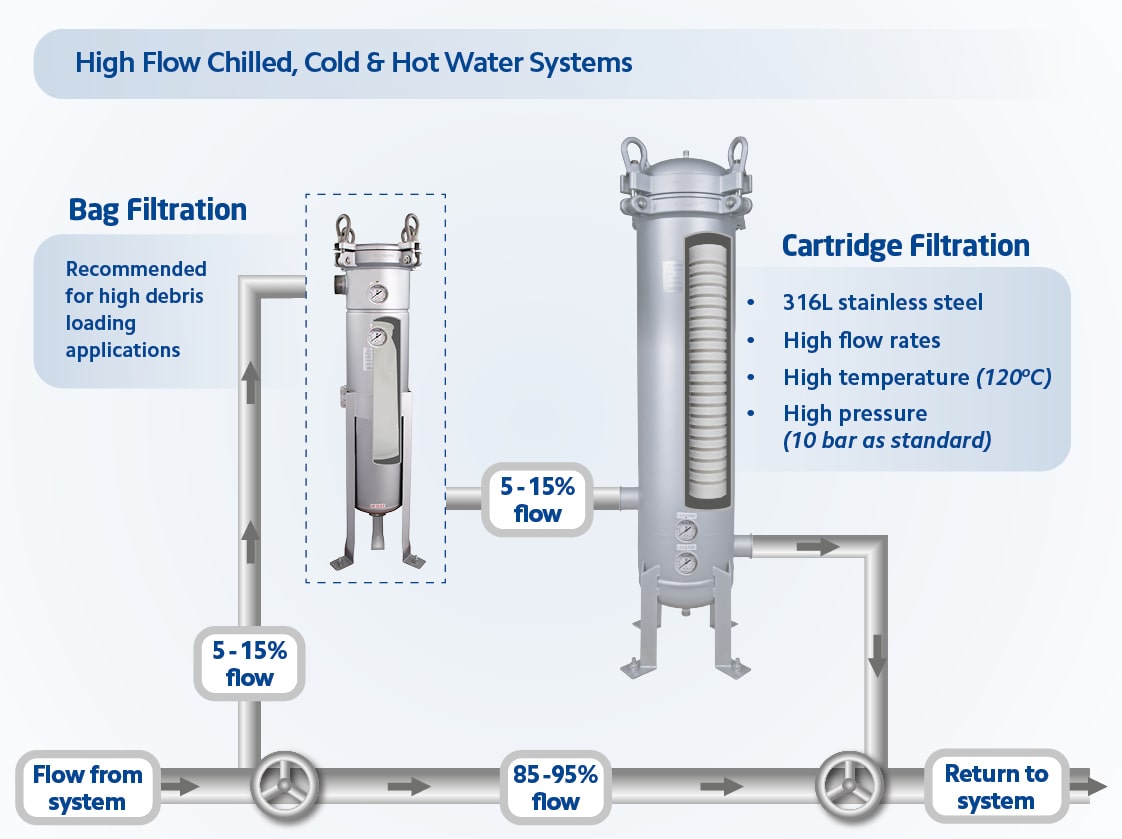

Side stream filtration can prolong the life of pipework as well as helping to improve energy efficient control strategies, by minimising the risk of blocking or reducing liquid flow rates. It is strongly recommended for systems over 2.5m3 litres, with typically 5-15% of the water being diverted from the circulation system, to remove contamination down to 1µm in size.

Side Stream Filtration System

Installing a side stream filtration system, comprising of a 316L stainless steel cartridge housing holding filter cartridges, filters the water by diverting a proportion of the flow through the system, continuously removing excess contamination. Higher flow systems use multi-round cartridge housings (protected by bag filtration in heavy loading applications) and lower flow systems use single-round cartridge housings.

Fileder recommends that for such demanding applications SPECTRUM Inox stainless steel filter housings are suitable, as they are designed to operate with the toughest liquid environments involving filtration.

For LTHW systems which typically require temperature compatibility of around 80ºC, Fileder recommends the use of the SPECTRUM SWC cotton wound filter cartridges. Although, these systems do not generally reach above 85oC, Fileder supplied wound cotton filters, with a stainless steel core, can be used in applications where temperatures reach up to 120oC and are available to remove contamination between 1 and 100µm.

Alternatively, where temperature resistance is not a priority, such as in CHW systems, Fileder recommends the use of either Premier or Standard TruDepth Spun filters which, thanks to their grooved construction, offer enhanced dirt holding capacity.

Plastic housings can be used in low temperature and low flow applications utilising the pre-assembled plastic housing systems ECONOMIC Filter Housing Systems (EFHS).

Chilled, Cold, Low, Medium and High Temperature Hot Water Systems (CHW, CWS, LTHW, MTHW and HTHW) all benefit from the use of side stream filtration systems to reduce ongoing maintenance costs.

What else to be mindful of with pipework cleaning

The removal of suspended solids also helps to limit contamination from waterborne microorganisms. Despite being chemically treated, the pipework can provide ideal conditions for bacterial growth. To avoid this, filters used should be easy to maintain and where possible, the system should be fitted with differential pressure gauges so that the filter cartridges can be replaced before clogging to keep the system running efficiently.