When you operate a dental surgery, you need peace of mind that your operation can access clean and pure water that meets your high standards of practice and the regulated guidance provided under HTM 01-05 and the Health and Safety at Work Act 1974.

This states that Registered dental practice managers have a duty of care which includes responsibility for ensuring that water supply, distribution and storage is compliant with best practice guidelines.

Challenges of yesterday’s systems

In the past, dentists have used piped and sprayed water to provide patients with mouth-rinsing water, but there have been risks associated with these methods. Firstly, there have been incidences of bacteria found in aerosol water, with Legionella, Pseudomonas and Mycobacteria spp all providing specific risks to patients.

Secondly, mineral deposits from piped water are known to damage the highly-sensitive and specialist equipment used in a dental surgery. Thirdly, traditionally, sterilisers have been fed by reverse osmosis systems that have always required regular cleaning and maintenance, with many at risk of providing poor quality water (meaning the steriliser alarms) or take time to produce pure enough water whilst creating waste water, this combination of issues can compromise the steriliser risking the health and safety of patients and the practice as a whole.

The risks of water aerosols

Research commissioned by the Care Quality Commission has found that the bacteria present in dental waterlines can be huge – with one particular study demonstrating bacterial colony sizes of 19,500 CFUs, compared to just 100 CFUs in standard drinking water.

Dental waterline supply is particularly critical as it comes into contact with open wounds and cuts from surgery. Contaminated water aerosols have also been found to result in occupational health risks to dental teams.

Patients with compromised immune systems or conditions such as chronic respiratory diseases will be at particular risk from bacterial colonisation or infection from inhaling water aerosols that are contaminated.

A better alternative

Happily, the latest range of targeted water filtration and treatment solutions take all guesswork out of the equation, remove the use of the reverse osmosis system and ensure that you and your patients can enjoy total peace of mind.

Benchtop sterilisers are now the standard solution found for instrument cleaning in most dental surgeries and are used before and after dental procedures. Naturally, due to the nature of the dental treatments, it is essential that a benchtop steriliser can be fed with reliably pure water.

At Fileder, we have years of specialist water cleansing and purification experience and offer the latest cutting-edge, targeted technologies that are designed for exacting industries such as dentistry, medical and healthcare.

The Fileder approach

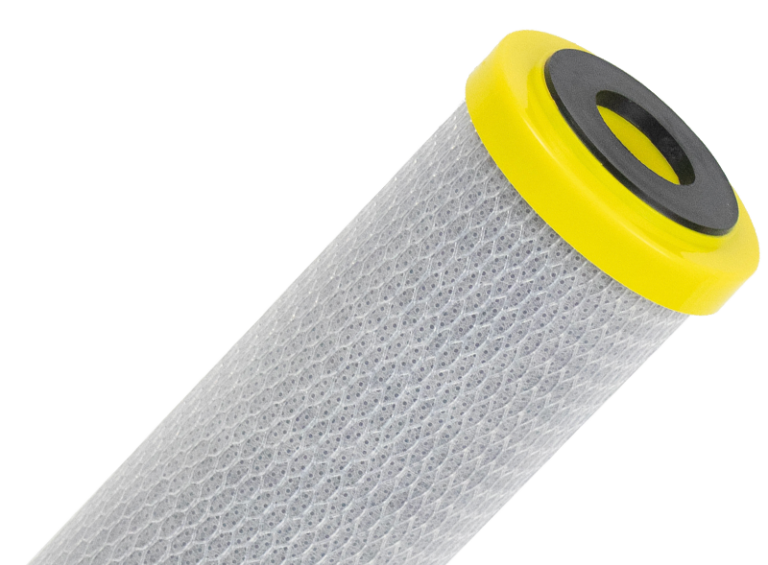

Before reaching the benchtop sterilisation stage, water will travel through an advanced cleansing and purification process. The water will be fed via pipes from the storage tank and then go through a process to remove sediment and organics, using a sediment removal cartridge and carbon block cartridge.

Next, it will be de-ionised using a pressure vessel and de-ionising resin to remove the salts and ions that form the TDS (Total Dissolved Solids) level. Bacteria and cyst removal then follows using an ultrafine hollow fibre filtration cartridge before the water is assessed by a TDS meter to check the water is pure enough to feed the steriliser. Options of system components mean all flow rates and planned maintenance schedules can be covered.

A Fileder, filtration and purification solution ensures that dentists receive the pure water that they need to feed their benchtop sterilisation systems with total peace of mind and compliance with the highest regulatory standards.

Our technology operates to the same impeccably high standards that the medical industries use and our experts work closely with dental surgeries of all kinds and sizes to implement the water purification solutions that they need to offer consistent patient care and an efficient, healthy and safe business.

ref: CQC