How Physical Filtration Can Lower Production Cost and Help Preserve Beer’s Unique Characteristics

Applying physical filtration in the brewery process could lower cost up to 40% by minimising beverage losses and can also improve water and energy consumption.

Filtration and pasteurisation are methods used to treat the potential for beer spoilage microorganisms and therefore prolong the shelf life of the beer.

Pasteurisation has been used for many years as a method of preserving beer and has been applied differently to achieve specific beer characteristics.

However, in some cases pasteurisation could contribute to significant losses in final beer volume. A whole batch can be sent to waste if inconsistency in temperature, pressure or flow rate is detected during the process. Also, it’s very likely that applying pasteurisation methods could negatively impact the flavour of beer by accelerating the ‘staling’ or ‘aging’.

Physical filtration on the other hand can remove the presence of spoilage organisms, haze from polyphenols and keeps appropriate yeast levels leading to a better method of controlling the flavour, stability, appearance and shelf life of the packaged products.

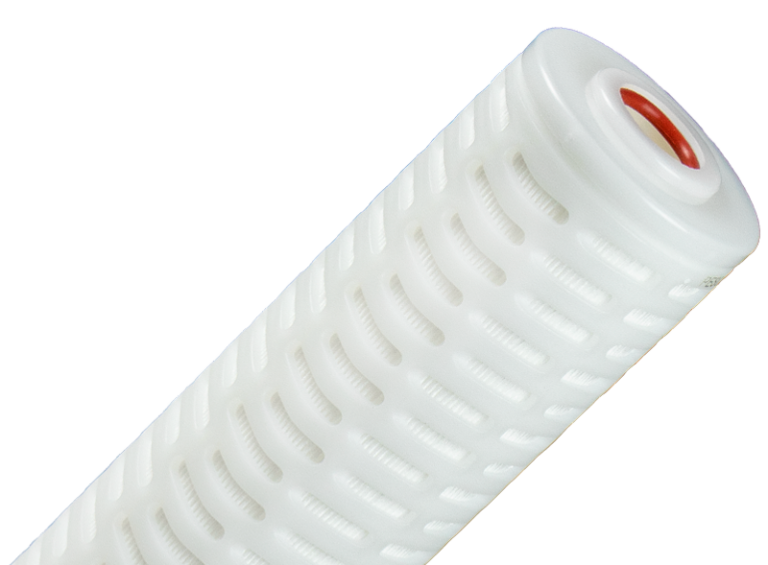

Fileder’s latest filtration technology incorporates a performance upgrade to a validated, integrity tested range of final stabilisation filter cartridges. The Bubble Point range or PES cartridges provides a unique alternative to brewers applying physical filtration. Certified to Log7 reduction of spoilage organisms this range provides reliable brew quality.

This innovative range uses a highly asymmetric PES membrane media, with an initial increased pore capacity that significantly improves performance and durability, so it’s critical for high load contaminant removal as found in beverage applications.

This new range extends membrane life in high loading applications and is suitable for use in many critical applications from biological filtration, through to the validated removal of spoilage microorganisms for beer, cider, wine and fruit juice classification.