Bottled water products have been in demand over the last decades because of more health-conscious lifestyle and convenience.

Bottled water comes as table, spring, mineral and flavoured varieties, still or sparkling in plastic or glass bottles. There are also water bottling companies that produce larger bottled water for dispensing in water coolers.

One of the challenges for bottled water producers is to achieve consistent products that match the elements desired including shelf life, appearance and quality.

For over 40 years, Fileder has supplied process filtration and water treatment solutions to the beverage industry.

Based on our experience, we have listed below 5 of the most common filtration steps:

1. Source filtration

Water sources are often a significant distance from the bottling site so the filtration process at this stage is focused on removing larger solids such as sediment and dirt before a UV system installation to keep the pipework and equipment cleaner by reducing bio-film growth.

Sediment, scale, organics and other materials present in water systems play an important role in providing favourable conditions for bacteria to thrive and must be controlled.

Bag filters and depth cartridges (SPECTRUM PSP) are typically used down to 5µm nominal to prevent ‘shadowing’ the UV light whereby organisms can be protected from the light by being in the shadows of dirt, sediment and debris.

2. Particle removal

This is the stage where fine particles are removed for further protection of the absolute rated filter cartridges downstream from premature clogging.

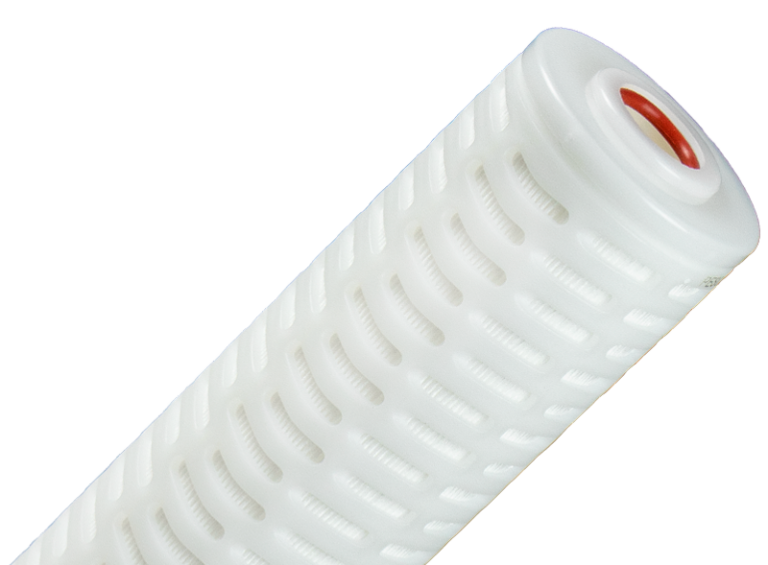

High efficiency pleated cartridges (SPECTRUM PPP) are used at this stage due to their exacting classification by using surface technology offering a high degree of control of elements in the individual’s water.

3. Parasite removal

Stage three is focused on removing parasites such as Cryptosporidium, a hard-shelled animal that needs to be physically removed to ensure that the consumer is protected.

Using surface filtration, a pleated cartridge with absolute rated glass fibre media will remove Cryptosporidium and other solids, protecting the final guard filter.

Fileder’s CRYPTO range of cartridges (SPECTRUM CP & CP+) is certified for Cryptosporidium removal.

4. Bacteria removal

This is the most critical stage within the bottling process as the producers need to ensure that the final product will not harm the consumer through bacterial contamination. Waterborne organisms are various with bacteria sized at 0.2µm or larger. For that reason, the final filters used to remove waterborne bacteria use media made with a membrane containing billions of pores to provide absolute rated efficiency of removal.

Premier Pleat Polyethersulfone (SPECTRUM PPPES) is certified log7 removal of bacteria ie. 99.99999% removal.

UV disinfection is often used before or after PPPES 0.2µm to treat water at the last possible moment before bottling.

5. Tank venting

Tank venting provides protection from contamination of stored water.

Air vents are designed for use with storage tanks to allow the tank to ‘breathe’ and for the removal of airborne bacteria.

Filters made with PTFE (Polytetrafluoroethylene) media are used in venting applications as this media is very hydrophobic, meaning it is resistant to sealing from the presence of moisture, splashes and condensations. Large tanks require a Premier Pleat Polytetrafluoroethylene (SPECTRUM PPPTFE) cartridge in a housing whereas smaller tanks can use the all in one Premier Pleat Air Vent PPPTFE-0.1-3.