Changing Customer Expectations

With tightened industry regulations, growing environmental concerns and increasing awareness among customers, there has been a notable shift in demand towards waterborne paints. To meet customer expectations, more and more producers are focussing their efforts on the production of paint which is less toxic to the environment and customers themselves.

Why bacteria free water?

Whilst these paints are less damaging than traditional biocidal paints, they frequently have higher water content, meaning they are prone to bacterial degradation and spoilage. Wetting agents, pigment dispersions and other aqueous raw materials, unless manufactured under bacteria free conditions, can become contaminated during production and may carry this contamination further to the finished product. Water unfortunately, is the largest agent for such contamination and therefore should be of specific concern to producers – a can of waterborne paint is the perfect environment for the bacteria to grow, as it provides minerals, oxygen and water. Thus, to minimise any risk of contamination, the water used must be controlled, so that other constituents are not affected by elements contained in the water. This requires manufacturers to rethink and adapt their production process, so that the risk of both product and cross contamination is limited.

Bag Filtration

The majority of producers are fully aware that product filtration is a crucial step in achieving better quality paint. To that end, paint manufacturers typically use bag filtration to remove lumps and gels that can form in the paint during production. These bags are mainly used in conjunction with stainless steel bag housings which allow for aggressive chemical cleaning after use. Whilst this is still a very effective solution for removing particles of various sizes from the final product, it is important to note, this solution will fail to prevent bacterial contaminations.

Fileder Solution

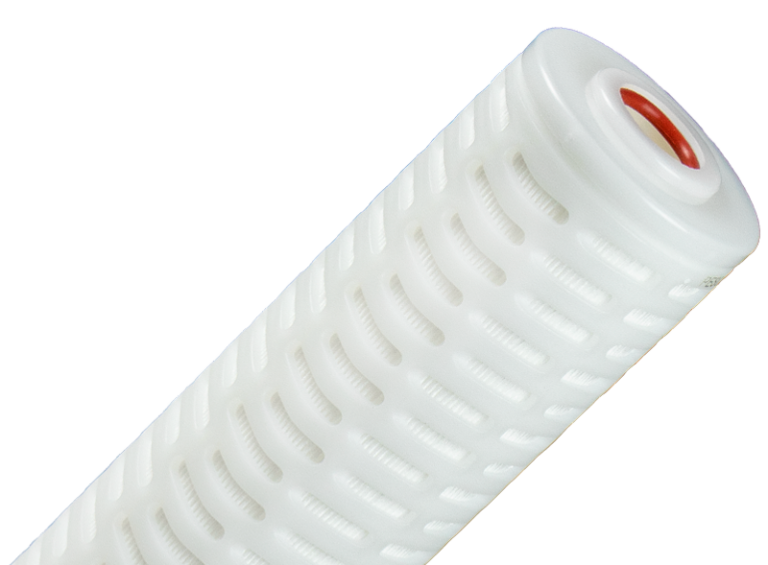

Fileder recommends that in addition to bag filtration, manufacturers should also implement effective bacteria removal techniques. Surface filtration should be applied to overcome this problem, offering excellent flow rates and high efficiency. You can find out more about how pleated filtration works here. SPECTRUM Premier Pleat Polyethersulfone has a layer of graded density PES membrane applied to the substrate which enables the absolute rated media to provide removal rates of bacteria such as Brevundimonas diminuta to 99.99999% (Log 7) assuring purity in the filtrate.

Bacteria contamination in water-based paints can lead to a number of serious issues for the manufacturer. A contaminated batch of paint would need to be removed and replaced across the whole supply chain, consequently having a direct impact on the production costs. It could lower the customer satisfaction score and essentially impact the overall brand image and reputation.