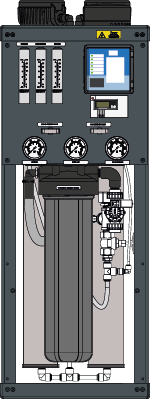

For the manufacture of a small medical items such as wound dressings, catheters, syringes, scalpels, artificial joints and many more similar devices, pure water is essential to keep the device clean, contaminant free and without bacterial deposits before they are hygienically packed for use.

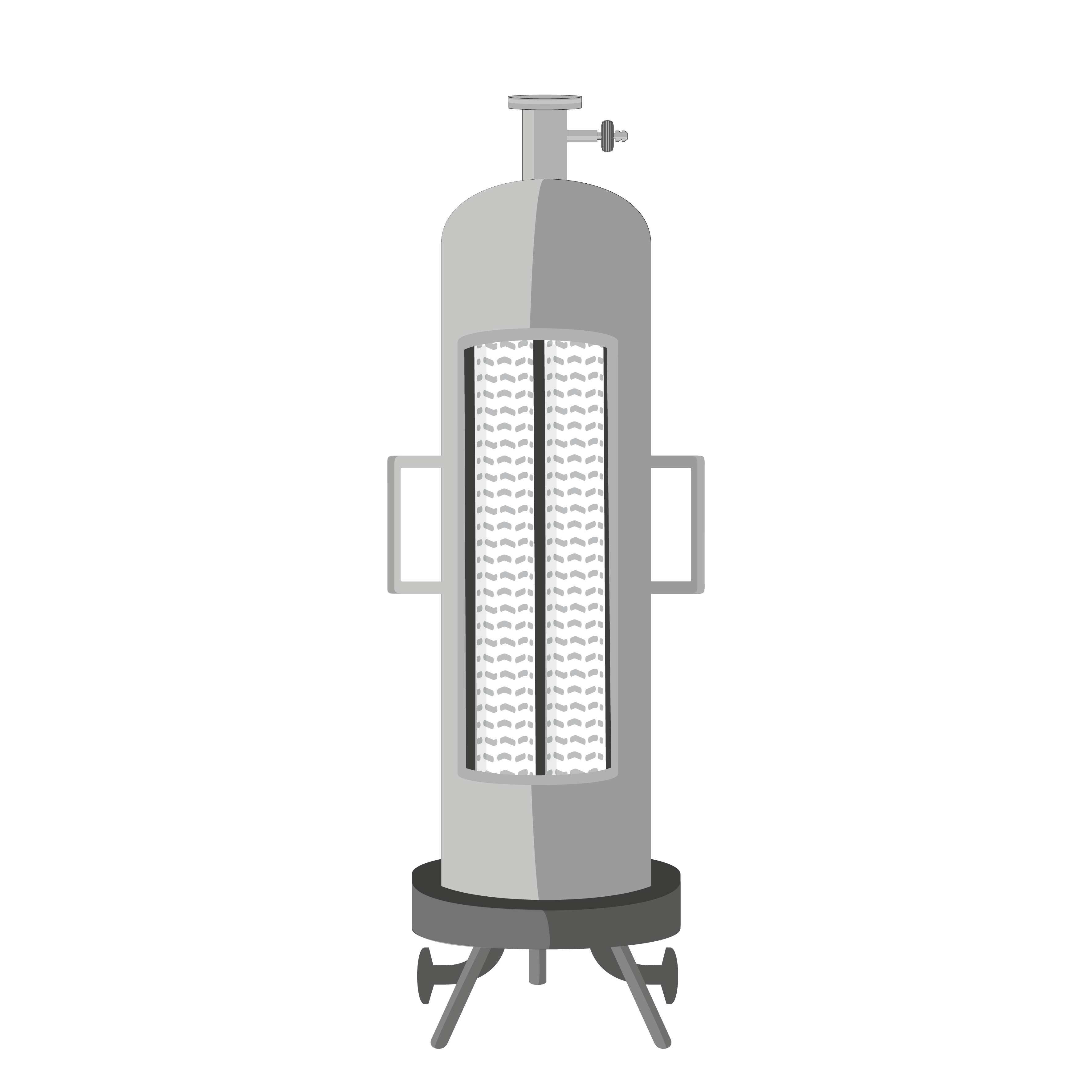

Due to the specialist nature of this industry, it often deionised (DI) quality water that is used as all ions and salts have been removed, leaving no surface imperfections. This water is then commonly passed through a bacteria removal filtration stage to avoid bacterial contamination.