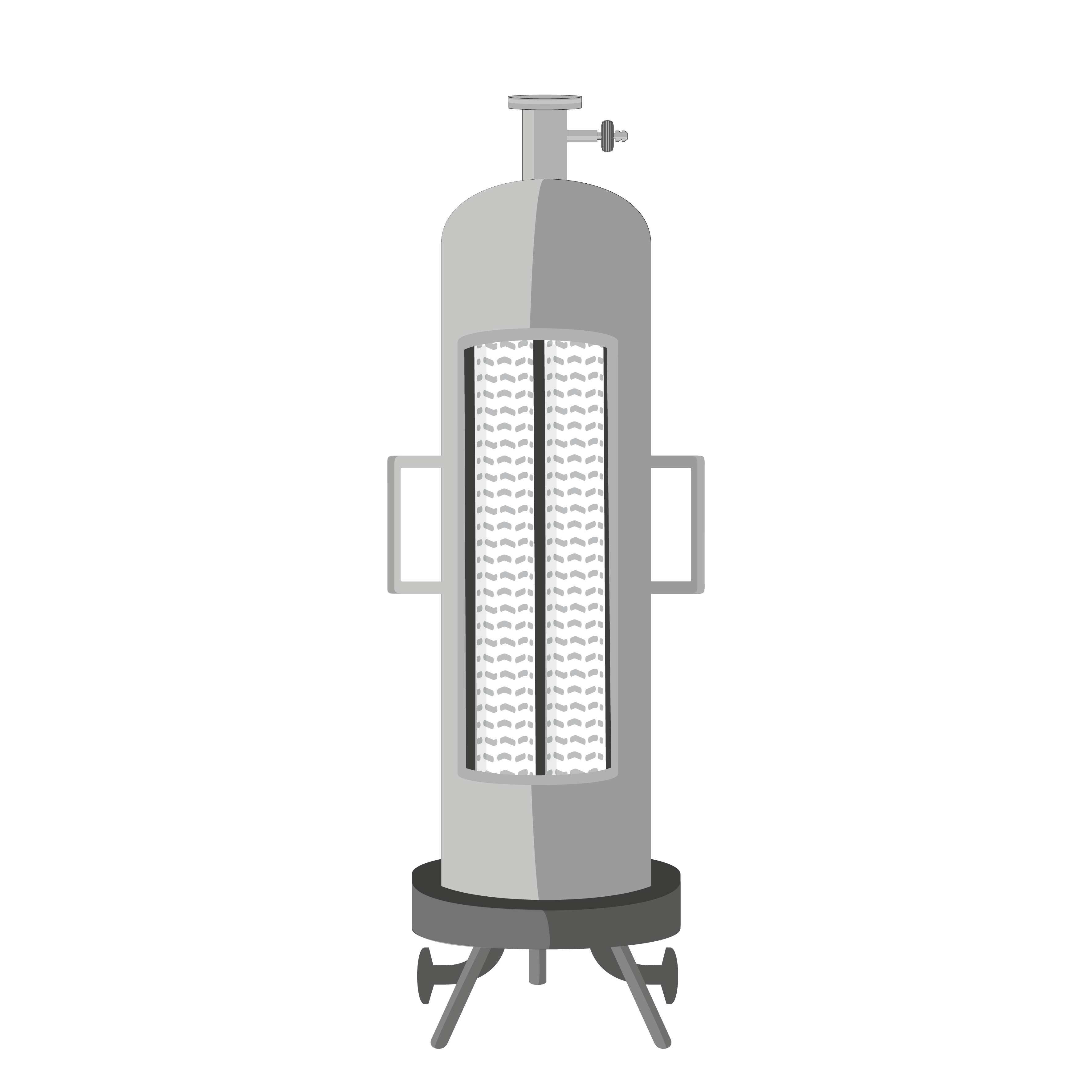

There are literally thousands of different formulations manufactured in the pharmaceutical industry. Liquid formulations are typically filtered before packaging to remove any oversized particles such as undissolved ingredients.

Due to the exact nature of the industry, validated pleated cartridges are often used for these ‘polishing’ applications.