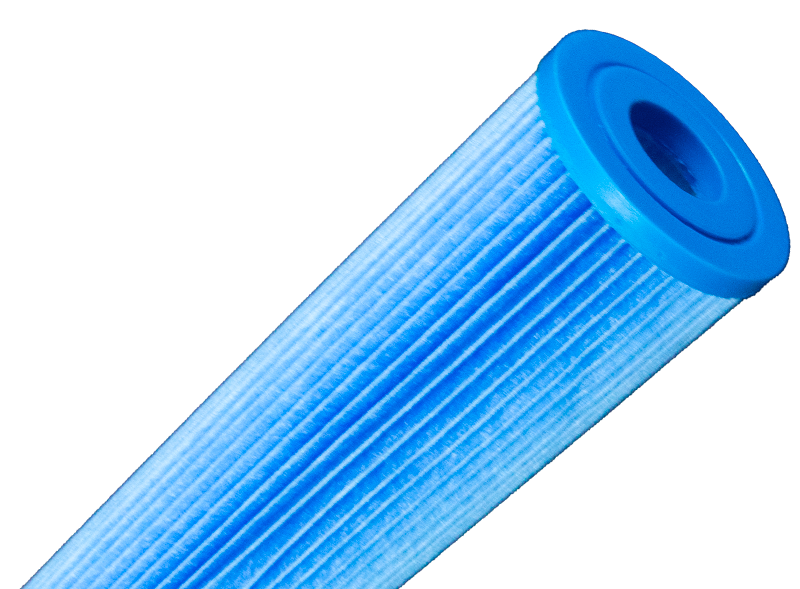

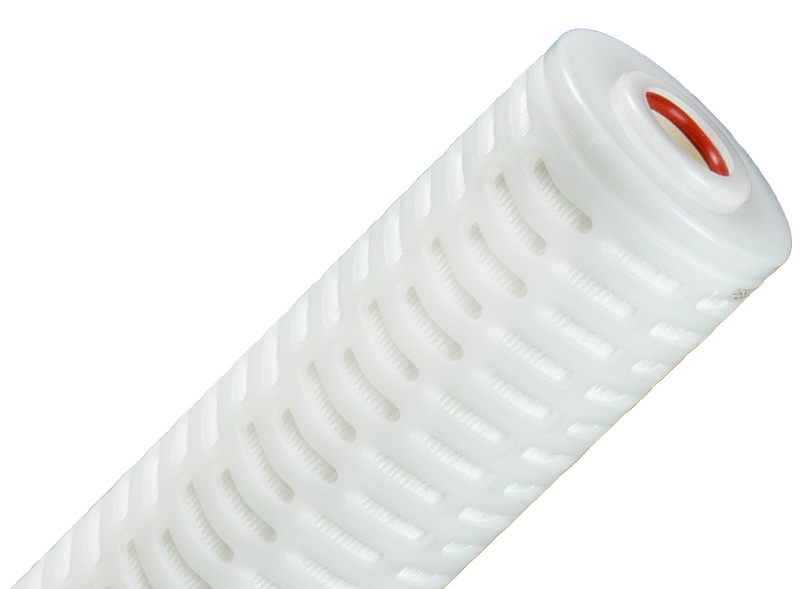

Surface filtration works at the cartridge’s media surface to remove specific particle sizes typically at a high removal efficiency. Surface filtration often utilises pleated filters with large surface areas, allowing the media to be tightly packed within the cartridge to maximise filtration efficiency. There are many different media types available in surface filtration, all designed to help with the removal of a range of contaminants such as bacteria, Cryptosporidium, cysts, silt and fine particulate. At Fileder, we offer a wide range of surface filtration solutions to suit a variety of industries.

Product range

SPECTRUM Standard Pleat Polypropylene (SPP)

SPECTRUM Standard Pleat Glass Fibre (SPG)

SPECTRUM Premier Pleat Polyethersulfone (PPPES-S)

SPECTRUM High Efficiency Premier Pleat (PPHP)

SPECTRUM Premier Pleat High Flow (PPG-HF)

SPECTRUM Pleat² Economic (EPE)

SPECTRUM Premier Pleat Depth Polypropylene (PPDP)

SPECTRUM Premier Pleat Polypropylene (PPP)

SPECTRUM Premier Pleat Polyethersulfone (PPPES)

SPECTRUM Premier Pleat Glass Fibre (PPG)

SPECTRUM Premier Pleat Nylon (PPN)

SPECTRUM Premier Pleat (PPPTFE)

SPECTRUM Bubble Point Beverage Filter Cartridge

SPECTRUM Crypto

SPECTRUM Premier Pleat High Flow (PPP-HF)

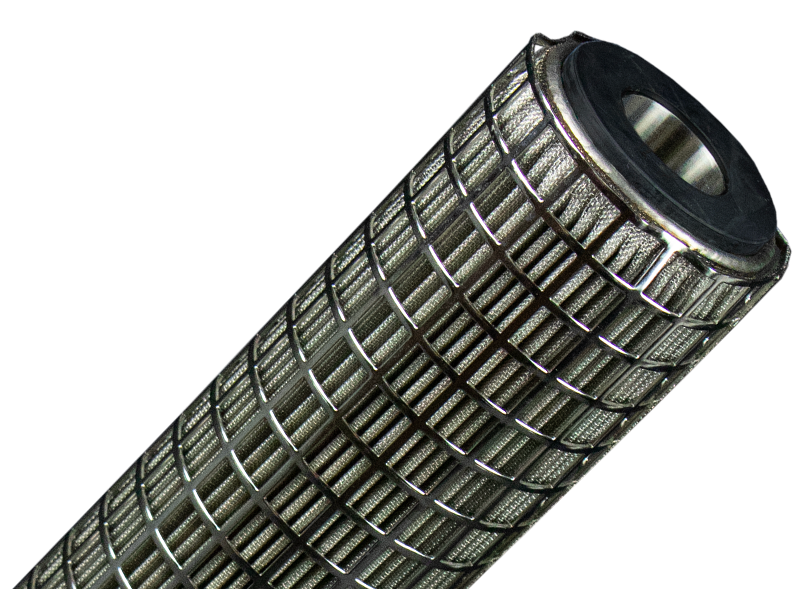

SPECTRUM Inox Standard Stainless Steel Pleated Cartridge (SPS)

SPECTRUM Inox Premier Stainless Steel Pleated Cartridge (PPS)

SPECTRUM Premier Pleat Air Vent

SPECTRUM Premier Pleat RinseCap Polyethersulfone Capsule

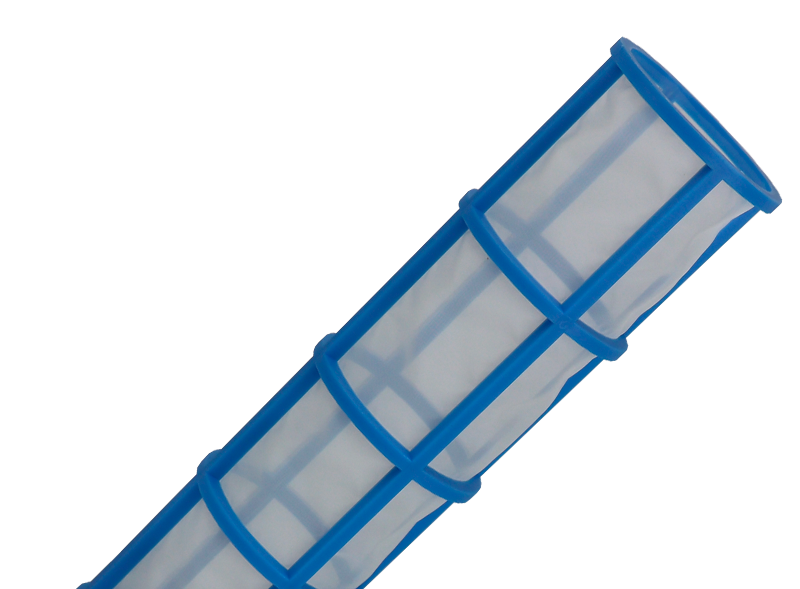

SPECTRUM Filter Sleeves

SPECTRUM Miniature Housings – SFH

How Does Surface Filtration Work

Surface filtration is a process where solids are separated from liquids. It’s typically used before chemical or biological treatments such as disinfection as the surface filters can’t withstand harsh chemicals. This process is just one method of treatment used to clean water used in various applications, playing a crucial role in removing large particulates that may have otherwise clogged the final filter stages.

Surface filtration is used in a wide range of industries, including, but not limited to:

- Pharmaceutical

- Manufacturing

- Food and beverage processing

- Automotive manufacturing

Buy Surface Filtration at Fileder

At Fileder, we offer a wide range of surface filtration products, including pleated cartridges, membranes, and screen filters. Each product is carefully designed for a longer service life, constant performance, and high efficiency in every application. Contact us today to discuss your needs, and our expert team can help give more information, recommend products, or provide a quote.